Over recent weeks I’ve been in the papermaking studio creating some new sheets for myself.

At the end of June my friend Dinah and myself pulped some unidentified plant fibre which quickly disintegrated and we had to add some other white pulp to the beater to produce something usable. I showed images of it here. I’ve now pulled some sheets from it as well as other pulp in the studio.

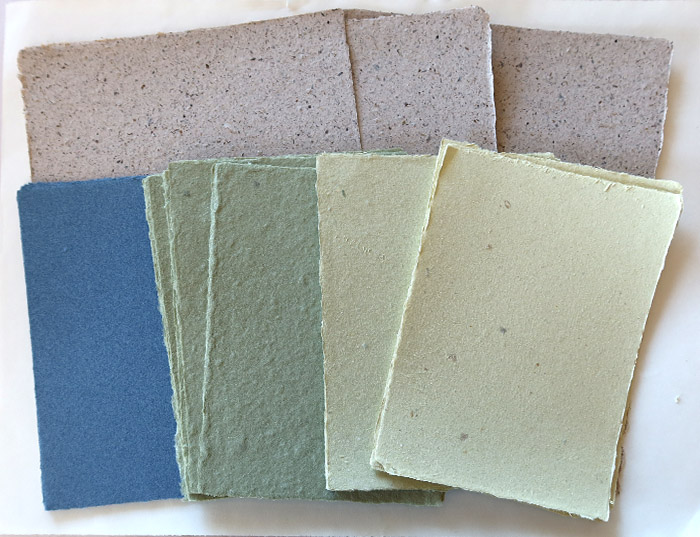

The top sheets are from the plant fibre/cotton rag pulp mix. The bottom row shows, from left to right: denim paper (from jeans), green hessian paper (from a hessian cushion cover), some hessian fibre mixed with yellow recycled folders, and finally just recycled yellow folders paper.

You’d think the paper from cardstock folders would be more vibrant as they are brightly coloured before we use them. However, I’ve found that many folders, when torn, are actually white inside – the colour is only a coating. So once they are shredded and pulped they often end up a lighter creamy tint of their original exterior. That’s what has happened in the ‘yellow’ papers shown here. In my case, it makes them more usable than bright primary coloured sheets.

Hello Claire. You echo my experience. The folders are a good, strong colour on the surface, but inside they are white. So the red ones gave me pinkish paper. It’s nice paper, but the colour is not so strong.

Hi Jacky, I’m very pleased with these results but it’s annoying when you actually want the strong colours for a specific purpose because it’s not always easy to get them. Dinah and I have worked with numerous pulps over recent years and sometimes when you manage to find a brightly coloured start paper – it might be tissue or other thin papers – they often bleed out into the water. So when you create your pulled paper stack (the post), ready for pressing, they bleed through to lower sheets.

I’ve some deep red coloured hessian, similar style to the origin of the green sheets I’ve shown here, and it might be time to pulp it to see if that works. I’ll soak a bit and see if the colour comes out of it. Surely if it’s made for home furnishings it has to be colour-fast.

It’s so exciting to see the variety of papers we end up with when we’re using a variety of materials. I’m very pleased with the denim paper that we made.

I have to say, Dinah, that the denim pulp you beat up has created the smoothest, most even sheets I’ve ever made. They lightened a little as they dried but are still a very strong vibrant colour. We’ll have to make some more soon so we can build our stashes for future projects.

Claire, thank you for the incredible information you have shared.

Are you just using pulped papers or is there an additive, a paste or a something to bond the pulp. I remember years ago we made paper and peeled and squeezed a peeled prickly pear leaf and obtained a substance like hair conditioner which was added to the pulp. Are you adding anything like that?

Hi Toni,there is nothing included as a formation aid or internal sizing. It’s simply the pulp from the items mentioned in the post for each one. That means the sheets can be used for any dry media: book-making, linocut, woodblock or gelli plate printing, acrylic painting and the like, but they can’t be re-wet or they will fall to pieces.